Soft Stone Quarries

To see a chart with different types of

stones and their properties, click

here.

Aside from mud brick, soft stone was the most

frequently used long-term building material in ancient Egypt. Within this rather

vague category, the limestone and sandstone dominated Egyptian architecture.

Though the characteristics of different types of these stones varied greatly,

the manner in which they were quaried did  not.

Limestone was used as a building material from the third Dynasty and was a

constant in Dynastic architecture ever after. It was quarried throughout the

east bank of the Nile near Cairo and the rest of the Delta region. Sandstone was

not introduced as a building material until the eleventh Dynasty and was found

between Esna and Gebel Barkal in Upper Egypt.

not.

Limestone was used as a building material from the third Dynasty and was a

constant in Dynastic architecture ever after. It was quarried throughout the

east bank of the Nile near Cairo and the rest of the Delta region. Sandstone was

not introduced as a building material until the eleventh Dynasty and was found

between Esna and Gebel Barkal in Upper Egypt.

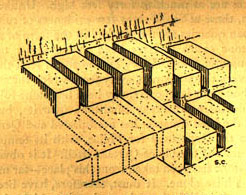

Both of these types of stone were extracted

mainly in the open quarry fashion. In this situation, masons and engineers would

look for a sloped area in which the bedrock was easily accessible. After

clearing any dirt, sand, and rubble from the rock face, workers would cut a grid

whose cells were separated by narrow working channels. Because of this, many

blocks could be worked at the same time. To remove a block, workers would dig

out about half of its underside and place blocks of wood in the newly created

spaces. Then channels would be flooded and the wood would be expanded, thus

breaking free the stone block. When combined with the shear size of some of the

quarries (notably that at Beni Hasan, which extended for miles), this system

allowed ancient Egypt to be able to produce soft stone in extremely high voloume

and at a relatively low cost.

Another factor that led to soft stone's high volume was the development of new

tools used to cut it. In order to cut a stone block from the bedrock, one would

use  both

metal and stone tools. As Rosemary Klemm showed in Stein und Steinbruche im

alten Agyptem, metals tools went through a significant evolution at the

beginning of the New Kingdom, when the copper that chisels were made from was

replaced by significantly more durable bronze.

both

metal and stone tools. As Rosemary Klemm showed in Stein und Steinbruche im

alten Agyptem, metals tools went through a significant evolution at the

beginning of the New Kingdom, when the copper that chisels were made from was

replaced by significantly more durable bronze.

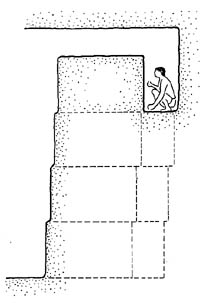

When compared to hard stones like granite, it

is easy to see why soft stones such as limestone were used to most often in

construction. The production speed and costs of hard stones could not compare

with those described above, and innovation in the techniques of their quarrying

were almost nonexistent. In special cirucumstances, however, the quarrying of

soft stones could be as expensive, time consuming, and dangerous as that of

granite. Often a builder would want to use only the best limestone, such as that

of Tura near Cairo. Any supplies near the surface of this extremely high-grade

stone quickly disappeared, but instead of looking for another source, quarrymen

often decided to construct covered quarries. Covered quarries were essentially

man-made caves that when fully exhausted could be hundreds of meters long. The

process by which these caves were extended (and thus stone was extracted) was

quite tedious. Workers would cut a small passage at the top of the back wall and

then cut down behind the block intended for removal, as in the diagram in this

page. To remove the block, the water and expanded wood system was used.

Top image (diagram showing method of extraction

in an open quarry) illustration from Ancient Egyptian Masonry

Lower image (section of a covered quarry) from

Building in Egypt: Pharaonic Stone Masonry

|| Library

List || Home || Report

Brokenlink ||

not.

Limestone was used as a building material from the third Dynasty and was a

constant in Dynastic architecture ever after. It was quarried throughout the

east bank of the Nile near Cairo and the rest of the Delta region. Sandstone was

not introduced as a building material until the eleventh Dynasty and was found

between Esna and Gebel Barkal in Upper Egypt.

not.

Limestone was used as a building material from the third Dynasty and was a

constant in Dynastic architecture ever after. It was quarried throughout the

east bank of the Nile near Cairo and the rest of the Delta region. Sandstone was

not introduced as a building material until the eleventh Dynasty and was found

between Esna and Gebel Barkal in Upper Egypt. both

metal and stone tools. As Rosemary Klemm showed in Stein und Steinbruche im

alten Agyptem, metals tools went through a significant evolution at the

beginning of the New Kingdom, when the copper that chisels were made from was

replaced by significantly more durable bronze.

both

metal and stone tools. As Rosemary Klemm showed in Stein und Steinbruche im

alten Agyptem, metals tools went through a significant evolution at the

beginning of the New Kingdom, when the copper that chisels were made from was

replaced by significantly more durable bronze.